R&D

Billion Rise’s experienced R&D team plans every production step carefully and provides professional design/development support to ensure customers can meet the needs of the fast-changing market. They provide expert advice in selecting the best print route possible among dyeing, digital, paper, rotary or flat bed to meet customer’s needs.

Knitting

Billion Rise offers a full synthetic product range consisting of both warp and weft knit fabrics.

- Warp Knitting Machines: Tricot, Raschel, Simplex, 28GG, 32GG, 36GG, 40GG.

- Weft Knitting Machines: Single Jersey, Double Knit (Interlock), 24GG, 28GG, 32GG, 36GG, 40GG, 44GG, 48GG, 52GG.

Dyeing

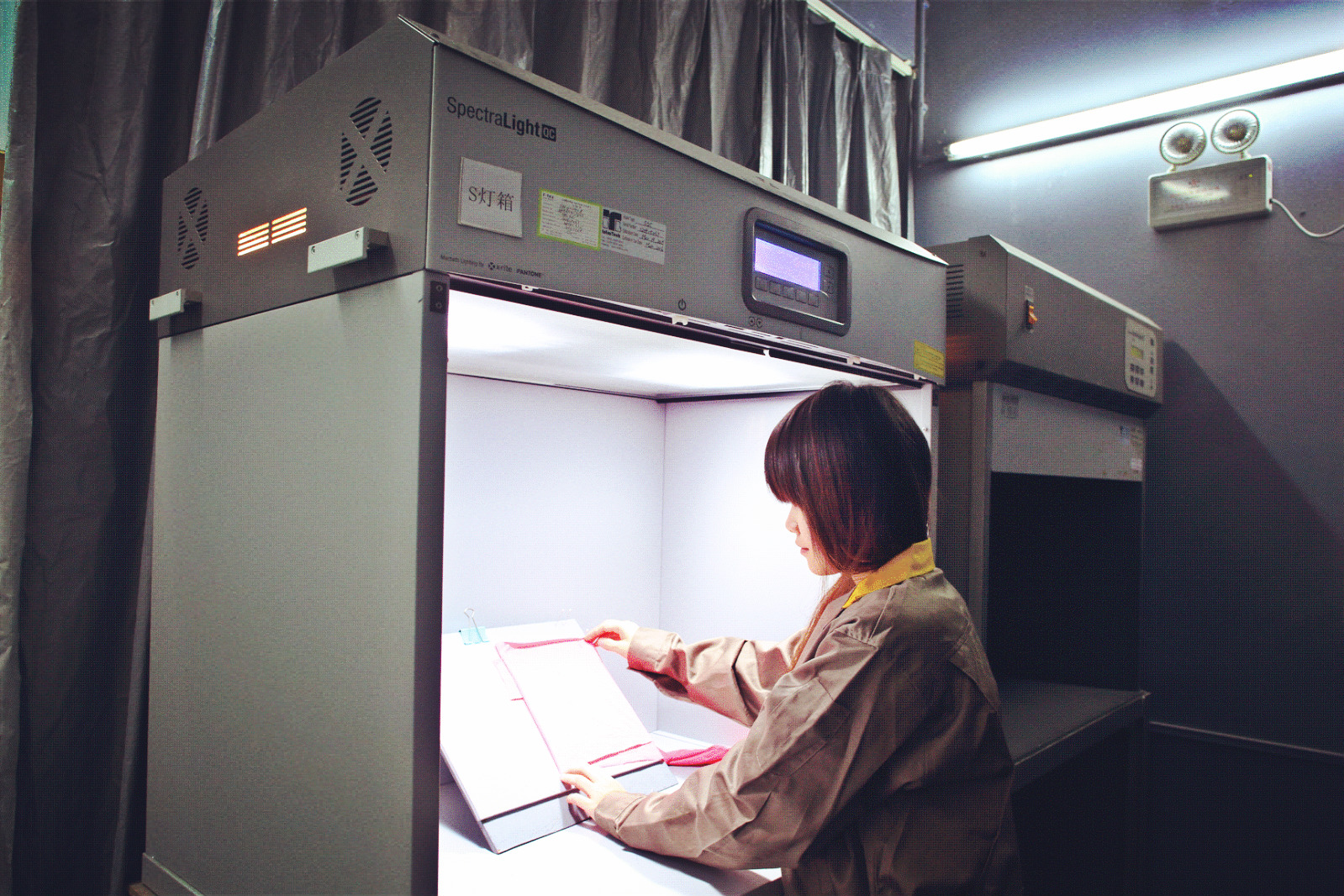

Billion Rise utilizes Auto LAB, Spectrum Reading Machine (Datacolor) and Auto Chemical Dispenser - fully automated production data management bringing vibrant colors and stability to your products.

State of the art machinery brings perfection to warp knit and weft knit fabrics. From raw materials to final product, from physical to chemical elements, your fabrics will have the best look and performance.

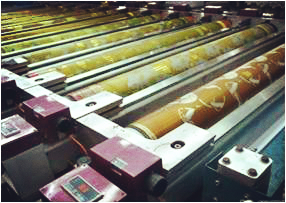

Billion Rise provides flatbed, rotary, digital and paper printing.

printing

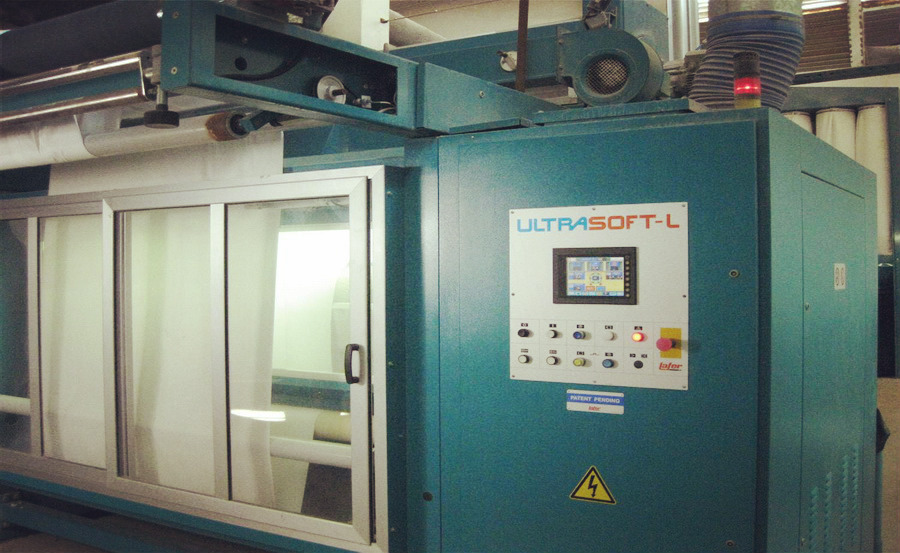

Billion Rise offers various special finishing, including, but not limited to, foil, brush, pigment print, quick dry, water repellent, antistatic, moisture wicking, antimicrobial, aloe moisturizing, aroma finishing and anti-UV.

FINISHING

Billion Rise uses Enterprise Resource Planning (ERP) professional production management system in every single department. The company is able to provide flexibility in production planning to fulfill different customer‘s requirements and assurance for high quality products. Using the industry standard 4 points inspection system for internal final inspection, the company applies rigorous quality control through all production departments, including real-time digital monitoring to the basic production element - water.